About Hot Isostatic Pressing (HIP)

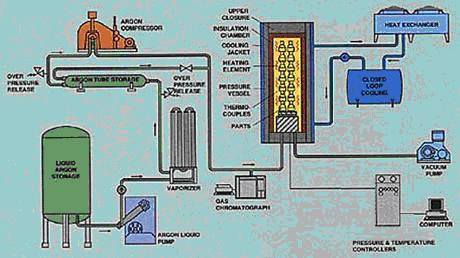

Hot Isostatic Pressing (HIP) is the simultaneous application of high temperature and pressure to metals and other materials for a specified amount of time in order to improve their mechanical properties. In the HIP unit a high temperature furnace is enclosed in a pressure vessel. The temperature, pressure and process time are all precisely controlled to achieve the optimum material properties. Parts are heated in an inert gas, generally argon, which applies "isostatic" pressure uniformly in all directions. This causes the material to become "plastic" allowing voids to collapse under the differential pressure. The surfaces of the voids diffusion bond together to effectively eliminate the defects achieving near theoretical density, while improving mechanical properties of the parts such as investment castings.

Hot Isostatic Pressing is a well established process for the improvement of a wide variety of materials such as titanium, steel, aluminum and superalloys. Using this process, voids within a casting can be reduced or eliminated and encapsulated powders can be consolidated to create fully dense materials. Also, similar and dissimilar materials can be bonded together to manufacture unique, cost effective components.

Hot Isostatic Pressing:

- When incorporated as an integral part of the manufacturing process reduces scrap and improves yield.

- Frequently allows replacement of wrought components by castings.

- Reduces quality assurance inspection requirements by improving material properties and reducing property scatter. Often, the savings on radiographic costs will cover the costs of HIP.

- Optimizes material properties.

- Parameters can be established to minimize subsequent heat treatment requirements.

- Processed parts exhibit enhanced reliability and extension of service life.

- Allows for smaller, lighter-weight parts with similar or superior performance.

- Can reduce the total production costs of a product.

Equipment Schematic of a Hot Isostatic Pressing System