HIP Applications

- Casting Densification

- Metal Powder Densification

- MIM Part Densification

- 3D Printed (AM) Part Densification

- Diffusion Bonding of Similar & Dissimilar Materials

- Densification of MMC's & Ceramics

- Rejuvenation of Creep Damaged Parts & Weldments

Aerospace Casting Densification

HIP is used to remove porosity from a wide range of nickel-based super alloy and titanium precision castings for aircraft engines and structural components.

Biomedical Device Densification

HIP is used in the medical industry to improve the properties of cast cobalt chrome, titanium and stainless steel implants.

Industrial Casting Densification

Industrial applications for hot isostatic pressing covers a wide range of industries and products such as electrical and electronic casings, machine tools and pump impellers.

Power Generation Casting Densification

In the power generation industry, hot isostatic pressing is used to densify turbine blades, discs and other components to remove porosity and enhance performance.

Additive Manufacturing & 3D Printing (Metal)

3D printing of metals combined with HIP processing offers the possibility to produce parts with qualities that are comparable to those resulting from conventional manufacturing methods.

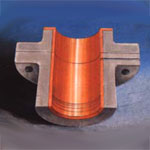

Diffusion Bonding

HIP is used in a range of applications to clad, weld and join dissimilar materials.

Powder Metallurgy (Consolidation) & MIM

Powder metal consolidation via HIP is used to produce both simple shapes for further processing and near net shape components faster, with reduced weight and less machining than traditional castings and forgings.